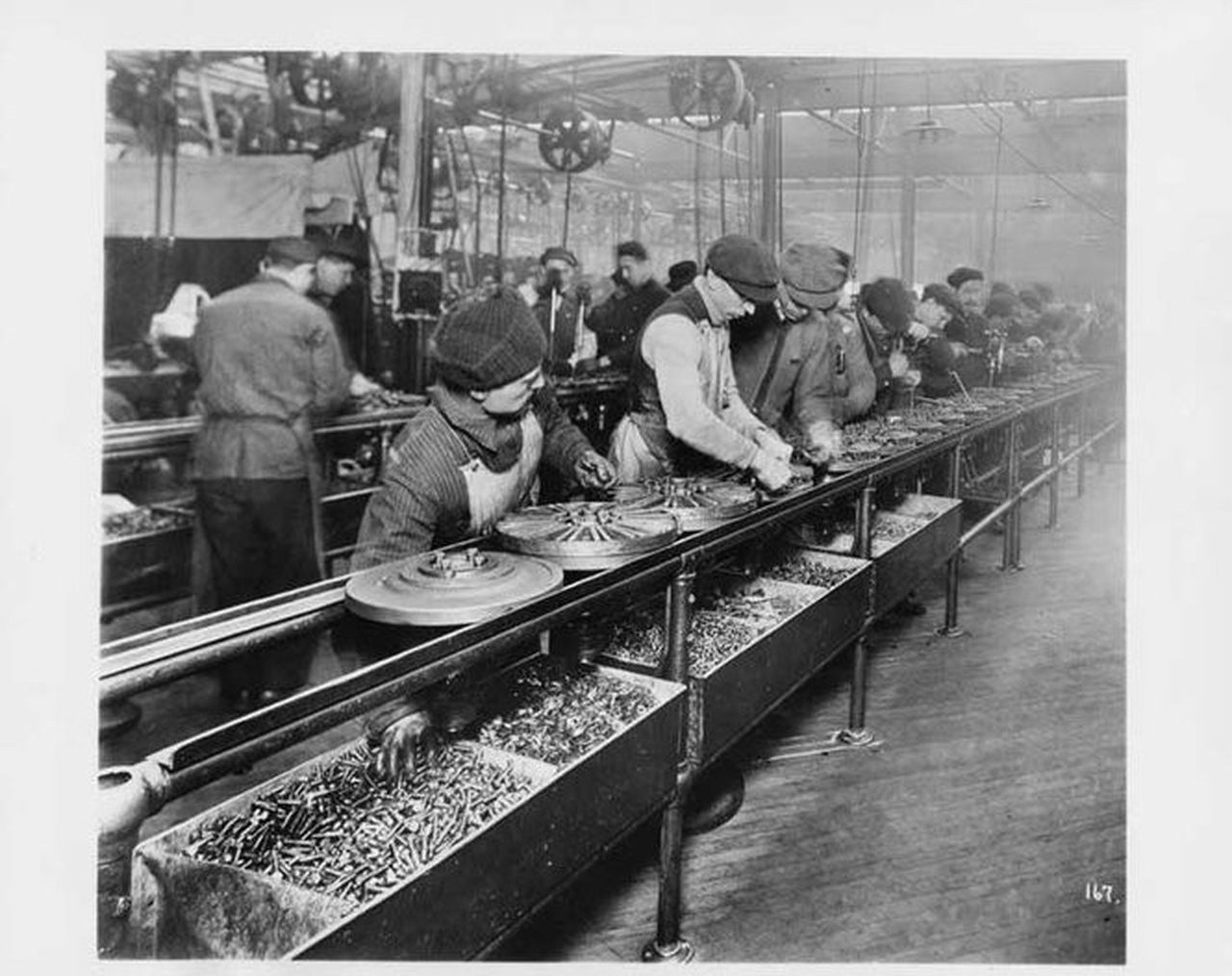

Assembly line workers milve.com

___________________________________________________________________________________________________________________

Before the assembly line, a lot of people didn’t have many jobs, and you needed to be trained to put an engine in or put the pedals, but with the assembly line anyone could put on a steering wheel or a light bulb.

The Model T was a quality vehicle and people wanted to buy it. Unfortunately, Henry could not produce them fast enough. So he came up with the idea of the assembly line, this process made producing cars faster and cheaper. It simplified assembly of the Ford Model T’s 3,000 parts by breaking it into 84 distinct steps. This new process of manufacturing brought the time to assemble a single vehicle from 12 hours to about 20 minutes. Before the assembly line method, the cars were selling for $850 ($23,000 in today’s money). By using the assembly line method to just about $300 ($8,000). For the first time in history, quality vehicles were affordable to everyone the middle-class. Eventually, Ford built a Model T every 24 seconds and sold more than 15 million worldwide by 1927.

In 1914, Ford instituted the “$5 workday,” a significant amount of money at the time. This enabled the people to buy the cars they built, purchase homes, decorate their homes, and support their families. The idea of a rich industrialist sharing profits with workers on such a scale was uncommon.

The Model T, sold by the Ford Motor Company from 1908 to 1927, was the earliest effort to make a car that most people could actually buy. The Model T was a car that could do anything. The car was able to go off-road, through water, and over small cliffs. The Model T was first available to the public in October 1908.

The car was very simple to drive, as well as easy and cheap to repair. Ford's network of dealerships planted around the country made sure that the car was available in virtually every city in North America. Sales skyrocketed across the country.

By the late 1920s, even Henry Ford could no longer ignore the decreasing sales models of the Model T. In 1927 he unwillingly shut down the Model T assembly lines and began designing an all-new car. It appeared in December of 1927 and was such a departure from the old Ford automobile that the company went all the way back to the beginning of the alphabet for a name, they called it the Model A. The new car would not be made at Highland Park. In 1917 Ford had started construction on an even bigger factory on the Rouge River in Dearborn, Michigan. Iron ore and coal were brought in on boats on the great lakes and by railroad.

By 1927, all steps in the manufacturing process from refining raw materials into the final assembly of the automobile took place at the vast River Rouge Plant, characterizing Henry Ford’s idea of mass production.